Welding, brazing, and soldering are all methods used to join two or more pieces of metal or other materials.

They are also used to fill gaps in metal parts.

So, how do you know which technique should be used?

It depends on the material, application, and desired strength.

Welding

Welding is used for creating a very strong connection between two pieces of metal.

They can withstand any sort of strains and stresses, e.g., aircraft fuselage or a car body.

What does welding include?

- Metals should be similar to weld them together.

For instance, copper can’t be welded to steel. - Welding of two metals together requires a very high temperature to melt and join them.

- Often, filler materials, such as an extra piece of metal, are used to seal any gaps.

- Properly done welding should be as strong as the unwelded metal surrounding it.

For example, the weld can be weakened by too much heat as well as characteristics of the metal can be changed. - Depending on the type of metal, there are various welding techniques.

You can learn which technique should be used with which metal in a welding program.

Various techniques have different sources of heat, e.g., lasers, electrodes, oxyacetylene gas, or ultrasonics.

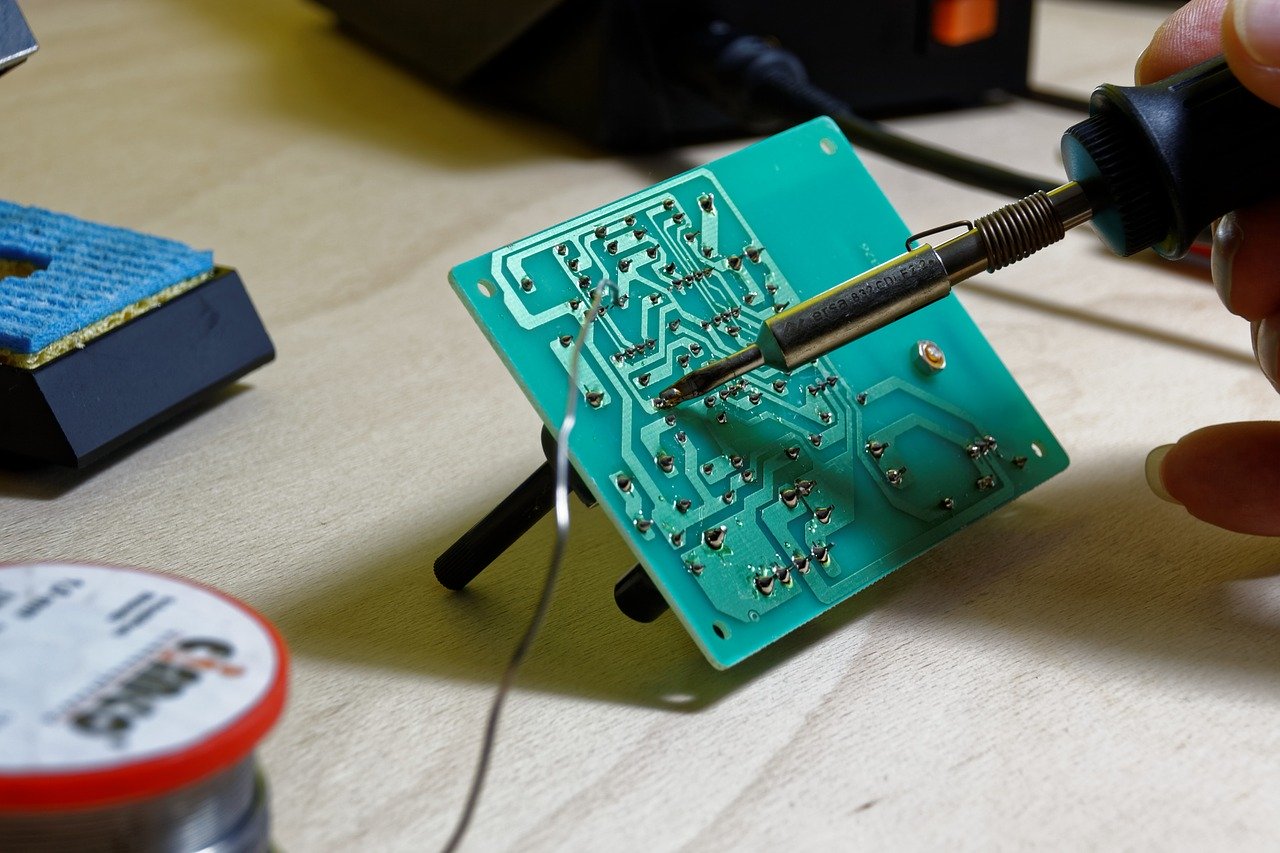

Soldering

Even though soldering may look similar to welding, it’s purpose is quite different.

Solder comes in tubes and reels and is rather soft.

It is used in electronic devices and allows the components in them to be connected with each other electronically.

What does soldering include?

- Contrary to welding, soldering uses low temperatures to join metal.

- Filler materials that melt at the temperature below 840 F degrees (450 C) are used in soldering.

- With soldering, different metals can be joined together, including gold, brass, silver, copper, and iron.

The bond is created when the soldered material solidifies. - A bond created by soldering isn’t as strong as brazed or welded one because the connection isn’t mechanical.

If soldering is done incorrectly, the pieces won’t properly conduct electricity. - Similar to brazing and welding, flux is used for cleaning of metal surfaces, so the solder could flow over the metal pieces that need to be joined.

Brazing

Similar to soldering, brazing uses filler material to join two metals but the high-temperature one.

Brazing also creates a mechanical connection between metal parts, like soldering.

So what does brazing include?

- Brazing is done by heating and melting the filler metal.

The pieces are joined when the filler solidifies. - The temperature of the filler material should have a lower melting temperature than the other pieces.

- With brazing, different metals can be joined, such as gold, silver, copper, nickel, or aluminum.

- Flux is also used to wet the metal parts which allows the filler flow over them to join the parts easier.

- The joins can be stronger than separate pieces when properly brazed, but they are not as strong as welded bonds.

Soldering, welding, and brazing are used to perform different jobs.

Depending on the work, you need to take into account such aspects as desired strength, type of metal, and the ultimate purpose to determine the right technique to join the metal parts.

With enough practice, you will master each technique.

Read the full guide: How to Become a Certified Welder